Coefficient of friction test – Mr. Caliper explains how it works

Mr. Caliper, what exactly is a coefficient of friction test?

The coefficient of friction is determined during the friction test. While tightening a screw or a nut, only a small part of the applied torque is converted into the clamp force of the connection. Most of the energy is transformed into heat during the friction. How high this amount is, depends on the coating and lubrication. The used testing components (washer and test nut) also effect the coefficient of friction. For this reason, testing parts in the DIN EN ISO 16047 are specified for the comparability of the results.

Why is it important?

Screw connections are tightened to a certain torque. To calculate the required torque, among other things, the desired preload force and the friction coefficient window are required. If the coefficient of friction is significantly higher than expected, the screw remains loose and the components cannot safely transmit the operating forces that occur, if it is too small, the screw elongates plastically or, in the worst case, tears off.

Which types of coefficient of friction tests can be performed in the laboratory of Würth Industri Norge?

We can perform friction coefficient test on screws and nuts with dimensions from M5 to M80 with our friction coefficient test stations. It is possible to perform tests according to the different norms e.g. DIN EN ISO 16047, DIN 14399-2 and VDA 235-203 (M5-M16). Tests can also be performed as close as possible on the application. For example, a certain lubricant or a counter thread carved out from a casing can be used individually for a test job. In addition to total friction coefficient, the friction in the contact surface and in the thread can also be determined.

Test sequence

Mr. Caliper is ready for the coefficient of friction test on products. Come with us and learn about the individual steps in detail!

The test samples must have a minimum length of approx. 4x nominal diameter for the test. The testing parts must comply with the normative requirements.

The testing parts must be prepared. For testing according to DIN EN ISO 16047, the laboratory of Würth Industry Service uses bright metallic testing parts (nut and washer) and degreases them in an ultrasonic bath with acetone.

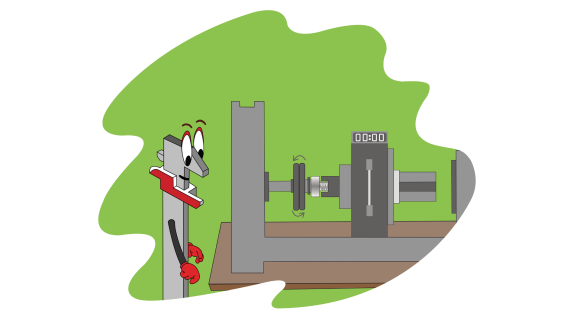

The to be tested sample is placed in the appropriate test fixture with the testing parts. The desired clamping length can be adjusted via spacers. During the test, the to be tested sample is always driven, the testing parts are fixed and thus secured against twisting.

The load cells are monitored every three months with reference samples and are also regularly calibrated.

During the test, the bolting assembly is tightened to 75% of the stress under proof load specified in DIN EN ISO 898-1 and the required tightening torque is recorded. The screw connection is then loosened. The amount of the tightening torque depends on the coefficient of friction and is calculated from the tightening torque.

The greater the friction, the higher the torque required to achieve the required clamp force. This can also be transferred to practical applications when it comes to the torque to be selected in the assembly in order to apply the required preload force to the connection if the coefficient of friction is known.

The test report describes the to be tested samples and the used testing parts. Furthermore, the tightening curves are graphically displayed and the results are listed. It is evaluated whether the coefficients of friction are within the specified tolerance range.

The Würth Industrie Service GmbH & Co. KG collects and processes the personal data provided in the form in order to process the requested request for you. Please note the mandatory fields in the forms. The legal basis for this processing, the absolutely necessary data, is Art. 6 para. 1 lit. b DSGVO, implementation of a pre-contractual measure. The processing of data voluntarily provided by you is carried out on the basis of Art. 6 para. 1 lit. f DSGVO. Thereafter, processing is permissible which is necessary to safeguard our legitimate interests. Our legitimate interest is to have contact with you, our customers, to improve our consulting quality and to be able to contact you more easily in case of possible queries. The data collected will only be stored by us for as long as is necessary to process your enquiry and to contact you. They are then deleted.

Supplementary data protection information, in particular regarding your rights to information, correction, deletion, restriction of processing, objection and complaint, can be found in our data protection declaration.